The Ultimate Guide to UV Printer Ink

UV printer ink has transformed the world of printing, introducing innovative features that are revolutionizing various industries. Unlike traditional inks, UV inks offer unique advantages such as faster drying times, enhanced durability, and the ability to print on a wider range of surfaces. This article delves into the details of UV printer ink, its applications, benefits, and the technology behind it, to help you understand why it's becoming essential in the printing landscape.

What is UV Printer Ink?

UV printer ink is a specialized ink that cures (dries) when exposed to ultraviolet (UV) light. This curing process allows the ink to become a solid layer on the surface of the material being printed on, providing vivid colors and sharp details that are often unmatched by conventional inks.

How Does UV Ink Work?

The functioning of UV printer ink is defined by its unique composition and the curing process. When the ink is applied to a substrate, it remains wet and workable until a UV light source triggers the curing process. This involves polymerization, where the ink molecules bond together to form a durable, solid coating. This not only ensures that the print adheres well to various surfaces but also enhances its longevity.

Advantages of UV Printer Ink

Understanding the benefits of UV printer ink is essential for businesses considering its application. Here are some key advantages:

- Rapid Drying: Unlike traditional inks that require time to evaporate and dry, UV inks cure instantly under UV light, streamlining production processes and enhancing workflow efficiency.

- Wide Range of Substrates: UV inks can adhere to a variety of surfaces, including plastic, metal, wood, glass, and even textiles. This versatility opens up numerous opportunities for businesses.

- Durability: Cured UV inks are resistant to scratches, chemicals, and fading, ensuring that prints maintain their quality and appearance over time.

- Vivid Colors: UV printer ink offers vibrant, high-quality color reproduction, enabling businesses to create striking visuals that stand out.

- Eco-friendly Options: Many UV inks are free from volatile organic compounds (VOCs), making them a healthier choice for both the environment and human health.

- Less Waste: Since UV inks are cured instantly, they minimize the risk of smudging and waste, making them a cost-effective option in the long run.

Applications of UV Printer Ink

The versatility of UV printer ink means that it can be implemented in a range of industries and applications. Here are some notable areas:

1. Signage and Displays

UV printing is extensively used in creating outdoor and indoor signage. The durability of UV inks ensures that signs can withstand various weather conditions while maintaining their colors and integrity.

2. Packaging

In the packaging industry, UV inks offer options for full-color prints on diverse materials, enhancing product visibility and appeal. Their quick curing time is an asset in fast-paced production environments.

3. Promotional Products

From promotional items like mugs and pens to customized giveaways, UV printer ink allows businesses to create eye-catching designs that attract customers’ attention.

4. Industrial Printing

In industries like electronics and automotive, UV ink is used for printing labels and components because of its resistance to chemicals and extreme conditions.

5. Fine Art and Photography

Artists and photographers are adopting UV printing for reproducing artwork and photographs on various substrates, providing a better finish and longevity than traditional methods.

The Technology Behind UV Printer Ink

The technology that fuels UV printer ink involves several critical components that ensure effective curing and printing:

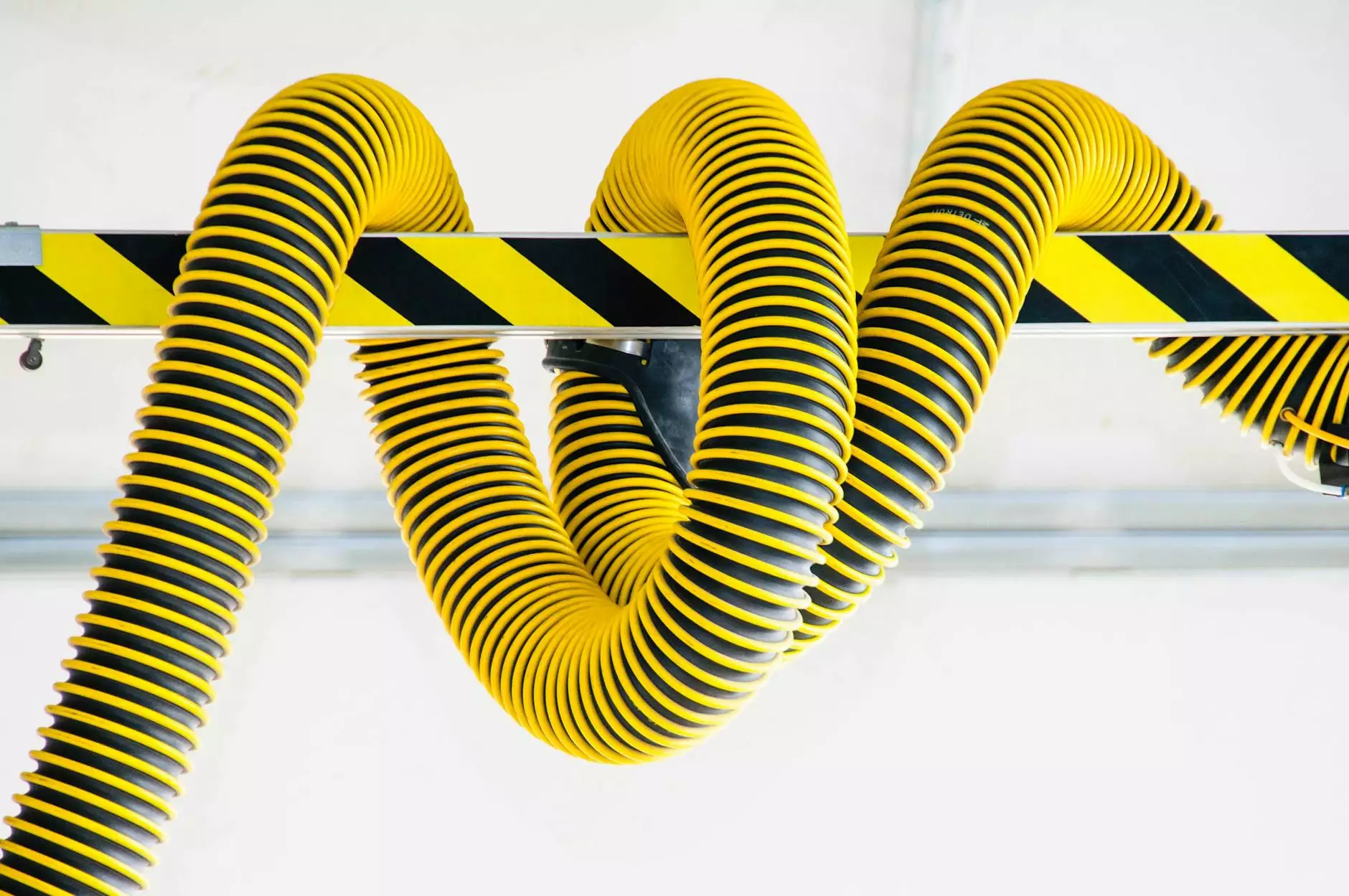

1. UV Light Sources

Modern UV printers incorporate sophisticated UV light sources, including mercury vapor lamps and LEDs, to quickly cure the ink as it is printed on materials. LED technology is gaining popularity due to its energy efficiency and longer lifespan.

2. Print Heads

UV printers utilize advanced print head technology, allowing for precise placement of ink droplets on substrates. This precision is key to achieving high-resolution prints.

3. Ink Formulation

The formulation of UV printer ink includes pigments, monomers, and photoinitiators that react under UV light. The quality of these ingredients directly affects the print quality and durability.

Choosing the Right UV Printer Ink

Selecting the right UV printer ink can significantly impact your printing outcomes. Here are some factors to consider:

- Substrate Compatibility: Ensure that the ink is compatible with the material you intend to print on, whether it's glass, plastic, or metal.

- Color Fastness: Different inks have varying levels of fade resistance. Choose inks that offer the durability your projects demand.

- Environmental Considerations: If sustainability is a priority for your business, look for inks labeled as eco-friendly or low in VOCs.

- Cost Effectiveness: Consider the long-term costs associated with the ink, including ink consumption rates and required maintenance.

- Supplier Reliability: Work with trusted suppliers who provide quality products and support services to maximize your investment in UV printing technology.

Common Misconceptions about UV Printer Ink

Despite its advantages, UV printer ink is surrounded by various misconceptions. Here, we clarify a few:

1. UV Inks are Harmful

While it’s true that some UV inks contain hazardous materials, many manufacturers are moving toward eco-friendly solutions, making the inks safer for both users and the environment.

2. UV Printers are Too Expensive

While the initial investment in UV printers can be higher than traditional printers, the long-term savings in reduced waste and faster production can offset these costs significantly.

3. UV Prints are Fragile

Contrary to this belief, once cured, UV prints are incredibly durable, resistant to scratches, and can withstand various environmental factors.

Conclusion

In conclusion, UV printer ink presents a wealth of opportunities for businesses in various sectors, with its ability to produce high-quality, durable, and vibrant prints across numerous substrates. By understanding the technology, applications, and advantages of UV inks, businesses can make informed decisions that enhance their printing capabilities. Investing in UV printing technology not only modernizes your processes but also positions your business for success in an increasingly competitive marketplace.

For more information about UV printing and how it can benefit your business, visit Boston Industrial Solutions. Our expertise in printing services ensures that you receive the quality and support necessary for your printing needs.